Expansion of Hong Kong International Airport into a Three-Runway System |

|

Construction Phase Monthly EM&A Report No.5 (For May 2016)

|

|

|

Chapter Title

1.2______ Scope of this Report

1.3______ Project Organisation

1.4______ Summary of Construction Works

1.5______ Summary of EM&A Programme Requirements

2.2______ Monitoring Requirements and Schedule

2.3______ Monitoring Equipment

2.4______ Monitoring Methodology

2.5______ Analysis and Interpretation of Monitoring Results

3.2______ Monitoring Requirements and Schedule

3.3______ Monitoring Equipment

3.4______ Monitoring Methodology

3.5______ Analysis and Interpretation of Monitoring Results

4.1______ Monitoring Requirements

4.2______ Waste Management Status

5.1______ Weekly Environmental Site Inspection

5.2______ Audit of Route Diversion and Speed Control of the SkyPier High Speed Ferries

5.3______ Status of Submissions under Environmental Permits

5.4______ Compliance with Other Statutory Environmental Requirements

6.1______ Construction Programme for the Coming Reporting Period

6.2______ Key Environmental Issues for the Coming Reporting Period

6.3______ Monitoring Schedule for the Coming Reporting Period

6.4______ Other EIA / EM&A Issues

Tables

The “Expansion of Hong Kong International Airport into a Three-Runway System” (the Project) serves to meet the future air traffic demands at Hong Kong International Airport (HKIA). On 7 November 2014, the Environmental Impact Assessment (EIA) Report (Register No.: AEIAR-185/2014) for the Project was approved and an Environmental Permit (EP) (Permit No.: EP-489/2014) was issued for the construction and operation of the Project.

Airport Authority Hong Kong (AAHK) commissioned Mott MacDonald Hong Kong Limited (MMHK) to undertake the role of Environmental Team (ET) for carrying out the Environmental Monitoring & Audit (EM&A) works during the construction phase of the Project in accordance with the Updated EM&A Manual.

This is the 5th Construction Phase Monthly EM&A Report for the Project which summarizes the monitoring results and audit findings of the EM&A programme during the reporting period from 1 May 2016 to 31 May 2016.

Key Construction Activities in the Reporting Month

The key construction activities of the Project carried out in the reporting month were related to Contract P560(R) Aviation Fuel Pipeline Diversion Works (Contract P560(R)) which involved installation of horizontal directional drilling (HDD) casing and antenna farm structural protection works. Dust suppression measures including wheel washing, watering and covering of excavated materials and establishment of site hoarding have been implemented.

No construction work was carried out on Sheung Sha Chau Island during the ardeid’s breeding season in the reporting month in accordance with the Updated EM&A Manual.

EM&A Activities Conducted in the Reporting Period

The monthly EM&A programme was undertaken in accordance with the Updated EM&A Manual of the Project. During the reporting period, the ET conducted thirty-three sets of air quality measurements, twenty-three sets of construction noise measurements, as well as four environmental site inspections, landscape & visual and waste monitoring for the Project’s construction works.

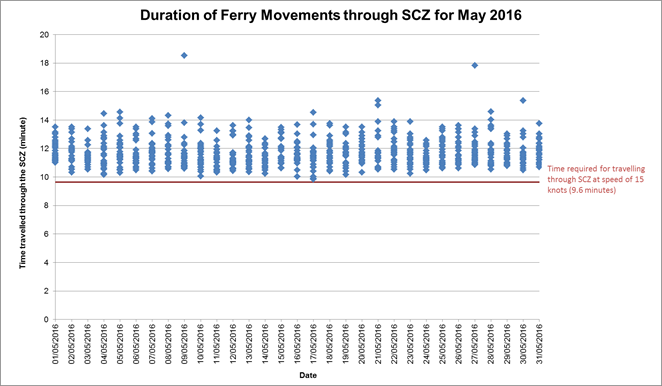

On the implementation of the SkyPier Plan, the daily movements of all SkyPier HSFs in May 2016 were within the maximum daily cap number. A total of 837 HSF movements under SkyPier Plan were recorded. All HSFs had travelled through the SCZ with prevailing speed under 15 knots (7.8 to 14.7 knots) in compliance with the SkyPier Plan. There was one case of not fully following the diverted route and investigation results revealed that the case was related to safety/emergency situations. In summary, the ET and IEC have audited the HSF movements against the SkyPier Plan and conducted follow up investigation or actions accordingly.

Results of Impact Monitoring

All scheduled 1-hour total suspended particulate (TSP), noise and waste monitoring were completed in the reporting period for the relevant construction activities. No exceedance of the Action/ Limit Levels was recorded.

Summary of Upcoming Key Issues

Major site activities anticipated in the next reporting period for the Project will be under Contract P560(R) including:

¡ HDD casing pipe installation; and

¡ Stockpiling of excavated materials from HDD operation.

The key environmental issues will be associated with dust and noise generation, surface runoffs and construction waste management. The implementation of required mitigation measures by the Contractor will be monitored by the ET. No construction works will be carried out on Sheung Sha Chau Island during the ardeids’ breeding season between April and July in accordance with the Updated EM&A Manual.

Summary of Other Key Environmental Issues

The progress of other related environmental surveys and baseline monitoring in this reporting month are as follows:

On-going:

¡ Baseline monitoring of Chinese White Dolphin (CWD) was on-going.

Completed:

¡ Baseline water quality monitoring had been completed in May 2016.

|

Laboratory analysis of samples of baseline water quality monitoring |

|

|

|

|

|

|

|

Measurement of heavy metals by Inductively coupled plasma mass spectrometry (ICP-MS) |

Laboratory measurement of suspended solids |

Laboratory measurement of nutrients |

Summary Table

The following table summarizes the key findings of the EM&A programme during the reporting period from 1 to 31 May 2016:

|

|

Yes |

No |

Details |

Analysis / Recommendation / Remedial Actions |

|

Breaches of Limit Level^ |

|

ü |

No exceedance of project-related limit level was recorded. |

Nil |

|

Breaches of Action Level^

|

|

ü |

No exceedance of project-related action level was recorded. |

Nil |

|

Complaints Received |

|

ü |

No construction activities related complaints were received. |

Nil |

|

Notification of any summons and status of prosecutions |

|

ü |

Neither notifications of summons nor prosecution were received. |

Nil |

|

Changes that affect the EM&A |

|

ü |

There were no changes to the construction works that may affect the EM&A |

Nil |

Remarks: ^ only exceedance of action/ limit level related to Project works will be highlighted.

1.1

Background

On 7 November 2014, the Environmental Impact Assessment (EIA) Report (Register No.: AEIAR-185/2014) for the “Expansion of Hong Kong International Airport into a Three-Runway System” (the Project) was approved and an Environmental Permit (EP) (Permit No.: EP-489/2014) was issued for the construction and operation of the Project.

Airport Authority Hong Kong (AAHK) commissioned Mott MacDonald Hong Kong Limited (MMHK) to undertake the role of Environmental Team (ET) for carrying out the Environmental Monitoring & Audit (EM&A) works during the construction phase of the Project in accordance with the Updated EM&A Manual (the Manual) submitted under EP Condition 3.1. The Manual is available on the Project’s dedicated website (accessible at: http://env.threerunwaysystem.com/en/index.html). AECOM Asia Company Limited (AECOM) was employed by AAHK as the Independent Environmental Checker (IEC) for the Project.

The Project covers the expansion of the existing airport into a three-runway system (3RS) with key project components comprising land formation of about 650 ha and all associated facilities and infrastructure including taxiways, aprons, aircraft stands, a passenger concourse, an expanded Terminal 2, all related airside and landside works and associated ancillary and supporting facilities. The existing submarine aviation fuel pipelines and submarine power cables also require diversion as part of the works.

Construction of the Project is to proceed in the general order of diversion of the submarine aviation fuel pipelines, diversion of the submarine power cables, land formation, and construction of infrastructure, followed by construction of superstructures. The land-based construction works of the Contract P560(R) Aviation Fuel Pipeline Diversion Works (Contract P560(R)) commenced on 28 December 2015 on the airport island.

The overall phasing programme of all construction works and the contract information of Contract P560(R) can be referred to Appendix A of the Construction Phase Monthly EM&A Report No. 1. Any changes/ updates of the construction programme and contract information will be reported in the Monthly EM&A report when necessary. Notably, on 29 April 2016, AAHK received the Chief Executive-in-Council’s approval for draft Chek Lap Kok Outline Zoning Plan, as well as the authorization of the reclamation under the Foreshore and Sea-bed (Reclamations) Ordinance for the expansion of HKIA into a 3RS.

1.2

Scope of this

Report

This is the 5th Construction Phase Monthly EM&A Report for the Project which summarizes the key findings of the EM&A programme during the reporting period from 1 to 31 May 2016.

1.3

Project Organisation

The Project’s organization structure remained unchanged during the reporting month. The Project’s organization structure and the contact details of the key personnel can be referred to Appendix B and Table 1.1 respectively of the Construction Phase Monthly EM&A Report No.1.

1.4

Summary of

Construction Works

During the reporting period, key construction activities of the Project were related to the Contract P560(R) Aviation Fuel Pipeline Diversion Works (Contract P560(R)) which involved installation of horizontal directional drilling (HDD) casing pipe at the HDD launching site located at the west part of the airport and associated structural protection works of the antenna farm located next to the HDD launching site.

The excavated materials from HDD operation were stockpiled at the stockpile area located near Chun Ming Road adjacent to Tradeport Logistic Centre on the airport island.

The HDD launching site and stockpiling area are around 3 km and 900m away respectively from the nearest air and noise sensitive receivers in Tung Chung and the villages in North Lantau. The locations of the Contract P560(R) works areas are presented in Figure 1.

1.5

Summary of

EM&A Programme Requirements

As presented in the Updated EM&A Manual, the environmental aspects of interest for the Project include air quality, noise, water quality, waste management, land contamination, terrestrial ecology, marine ecology, fisheries, landscape & visual, sewage and sewerage, and hazard to human life.

The status for all environmental aspects is presented in Table 1.1. The EM&A requirements remained unchanged during the reporting period and details can be referred to Table 1.2 of the Construction Phase Monthly EM&A Report No. 1.

Table 1.1: Summary of status for all environmental aspects under the Updated EM&A Manual

|

Parameters |

Status |

|

Air Quality |

|

|

Baseline Monitoring |

The baseline air quality monitoring result has been reported in Baseline Monitoring Report (Version 1) and submitted to EPD on 14 December 2015 under EP Condition 3.4. |

|

Impact Monitoring |

On-going |

|

Noise |

|

|

Baseline Monitoring |

The baseline noise monitoring result has been reported in Baseline Monitoring Report (Version 1) and submitted to EPD on 14 December 2015 under EP Condition 3.4. |

|

Impact Monitoring |

On-going |

|

Water Quality |

|

|

General Baseline Water Quality Monitoring for reclamation, water jetting and field joint works |

The baseline water quality monitoring had been completed in May 2016. The baseline water quality monitoring result will be presented in a separate Baseline Monitoring Report for the marine works. |

|

General Impact Water Quality Monitoring for reclamation, water jetting and field joint works |

To be commenced with the relevant construction works |

|

Initial Intensive Deep Cement Mixing (DCM) Water Quality Monitoring |

To be commenced with the relevant construction works |

|

Regular DCM Water Quality Monitoring |

To be commenced with the relevant construction works |

|

Waste Management |

|

|

Waste Monitoring |

On-going |

|

Land Contamination |

|

|

Supplementary Contamination Assessment Plan (CAP) |

To be submitted with the relevant construction works |

|

Contamination Assessment Report (CAR) for Golf Course |

The CAR for Golf Course was submitted to EPD on 17 March 2016. EPD had no adverse comment on the CAR for Golf Course on 6 April 2016. |

|

Terrestrial Ecology |

|

|

Pre-construction Egretry Survey Egretry Survey Plan |

The revised Egretry Survey Plan was submitted and approved by EPD on 25 April 2016 under EP Condition 2.14. |

|

Ecological Monitoring |

No construction work was carried out on Sheung Sha Chau Island during the ardeid’s breeding season in the reporting month in accordance with the Updated EM&A Manual. No ecological monitoring was conducted during the reporting month. |

|

Marine Ecology |

|

|

Pre-Construction Phase Coral Dive Survey |

The revised Coral Translocation Plan was submitted to EPD on 19 May 2016 under EP Condition 2.12. |

|

Chinese White Dolphins (CWD) |

|

|

Vessel survey, land-based theodolite track and passive acoustic monitoring (PAM) |

|

|

Baseline Monitoring |

On-going |

|

Impact Monitoring |

To be commenced with the relevant construction works |

|

Landscape & Visual |

|

|

Baseline Monitoring |

The baseline landscape & visual monitoring result has been reported in Baseline Monitoring Report (Version 1) and submitted to EPD on 14 December 2015 under EP Condition 3.4. |

|

Impact Monitoring |

On-going |

|

Environmental Auditing |

|

|

Regular site inspection |

On-going |

|

SkyPier High Speed Ferries (HSF) implementation measures |

On-going |

|

Construction and Associated Vessels Implementation measures |

To be commenced with the relevant construction works |

|

Complaint Hotline and Email channel |

On-going |

|

Environmental Log Book |

On-going |

Taking into account that the construction works in this reporting month were mainly land-based works of Contract P560(R), the required impact monitoring focused on air quality, noise, waste management and landscape & visual. The EM&A programme also involved weekly site inspections and related auditing conducted by the ET for checking the implementation of the required environmental mitigation measures recommended in the approved EIA Report.

The EM&A programme has been following the recommendations presented in the approved EIA Report and the Updated EM&A Manual. A summary of implementation status of the environmental mitigation measures for the construction phase of the Project during the reporting period is provided in Appendix A.

2.1

Monitoring

Stations

Air quality monitoring was conducted at two representative monitoring stations in the vicinity of air sensitive receivers in Tung Chung and villages in North Lantau in accordance with the Updated EM&A Manual. Table 2.1 describes the details of the monitoring stations. Figure 2 shows the locations of the monitoring stations.

Table 2.1: Locations of Impact Air Quality Monitoring Stations

|

Monitoring Station |

Location |

|

AR1A |

Man Tung Road Park |

|

AR2 |

Village House at Tin Sum |

2.2

Monitoring

Requirements and Schedule

In accordance with the Updated EM&A Manual, baseline 1-hour total suspended particulate (TSP) levels at the two air quality monitoring stations were established as presented in the Baseline Monitoring Report (Version 1 dated December 2015). Impact 1-hour TSP monitoring was conducted for three times every 6 days. The Action and Limit Levels of the air quality monitoring are provided in Table 2.2. The air quality monitoring schedule involved in the reporting period is provided in Appendix C.

Table 2.2: Action and Limit Levels for 1-hour TSP

|

Monitoring Station |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

AR1A |

306 |

500 |

|

AR2 |

298 |

2.3

Monitoring

Equipment

Portable direct reading dust meter was used to carry out the 1-hour TSP monitoring. The brand and model of the equipment are given in Table 2.3.

Table 2.3: Air Quality Monitoring Equipment

|

Equipment |

Brand and Model |

|

Portable direct reading dust meter (Laser dust monitor) |

SIBTA LD-3B-002 (Serial No. 974350) |

2.4

Monitoring

Methodology

2.4.1

Measuring

Procedure

The measurement procedures involved in the impact 1-hr TSP monitoring can be summarised as follows:

a. The portable direct reading dust meter was mounted on a tripod at a height of 1.2 m above the ground.

b. Prior to the measurement, the equipment was set up for 1 minute span check and 6 second background check.

c. The one hour dust measurement was started. Site conditions and dust sources at the nearby area were recorded on a record sheet.

d. When the measurement completed, the “Count” reading per hour was recorded for result calculation.

2.4.2

Maintenance and

Calibration

The portable direct reading dust meter is calibrated every year against high volume sampler (HVS) to check the validity and accuracy of the results measured by direct reading method. The calibration certificates of the portable direct reading dust meter are provided in Appendix B. The corresponding calibration record of the HVS is also given in Appendix B.

2.5

Analysis and

Interpretation of Monitoring Results

The monitoring results for 1-hour TSP are summarized in Table 2.4. Detailed impact monitoring results are presented in Appendix D.

Table 2.4: Summary of 1-hour TSP Monitoring Results

|

Monitoring Station |

1-hr TSP Concentration Range (mg/m3) |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

AR1A |

6- 108 |

306 |

500 |

|

AR2 |

9- 78 |

298 |

No exceedance of the Action /Limit Level was recorded at all monitoring stations in the reporting period.

General meteorological conditions throughout the impact monitoring period were recorded. Wind data for each monitoring day including wind speed and wind direction was collected from the Chek Lap Kok Wind Station.

3.1

Monitoring Stations

Noise monitoring was conducted at five representative monitoring stations in the vicinity of noise sensitive receivers in Tung Chung and villages in North Lantau in accordance with the Updated EM&A Manual. Figure 2 shows the locations of the monitoring stations and these are described in Table 3.1 below. As described in Section 4.3.3 of the Updated EM&A Manual, monitoring at NM2 will commence when the future residential buildings in Tung Chung West Development become occupied.

Table 3.1: Locations of Impact Noise Monitoring Stations

|

Monitoring Station |

Location |

Type of measurement |

|

NM1A |

Man Tung Road Park |

Free field |

|

NM2(1) |

Tung Chung West Development |

To be determined |

|

NM3A |

Site Office |

Facade |

|

NM4 |

Ching Chung Hau Po Woon Primary School |

Free field |

|

NM5 |

Village House in Tin Sum |

Free field |

|

NM6 |

House No. 1, Sha Lo Wan |

Free field |

Note: (1) As described in Section 4.3.3 of the Updated EM&A Manual, noise monitoring at NM2 will only commence after occupation of the future Tung Chung West Development.

3.2

Monitoring Requirements and Schedule

In accordance with the Updated EM&A Manual, baseline noise levels at the noise monitoring stations were established as presented in the Baseline Monitoring Report (Version 1 dated December 2015). Impact noise monitoring was conducted once per week in the form of 30-minute measurements of Leq, L10 and L90 levels recorded at each monitoring station between 0700 and 1900 on normal weekdays. The Action and Limit levels of the noise monitoring are provided in Table 3.2. The construction noise monitoring schedule involved in the reporting period is provided in Appendix C.

Table 3.2: Action and Limit Levels for Construction Noise

|

Monitoring Stations |

Time Period |

Action Level |

Limit Level, Leq(30mins) dB(A) |

|

NM1A, NM2, NM3A, NM4, NM5 and NM6 |

0700-1900 hours on normal weekdays |

When one documented complaint is received from any one of the sensitive receivers |

75 dB(A)(i) |

Note: (i) reduce to 70dB(A) for school and 65dB(A) during school examination periods.

3.3

Monitoring

Equipment

Noise monitoring was performed using sound level meter at each designated monitoring station. The sound level meters deployed comply with the International Electrotechnical Commission Publications 651:1979 (Type 1) and 804:1985 (Type 1) specifications. Acoustic calibrator was used to check the sound level meters by a known sound pressure level for field measurement. The brand and model of the equipment are given in Table 3.3.

Table 3.3: Noise Monitoring Equipment

|

Equipment |

Brand and Model |

|

Integrated Sound Level Meter |

B&K 2238 (Serial No. 2800932) B&K 2238 (Serial No. 2381580) |

|

Acoustic Calibrator |

B&K 4231 (Serial No. 3003246) B&K 4231 (Serial No. 3004068) |

3.4

Monitoring Methodology

3.4.1

Monitoring

Procedure

The monitoring procedures involved in the noise impact monitoring can be summarised as follows:

a. The sound level meter was set on a tripod at least a height of 1.2 m above the ground for free-field measurements at monitoring stations NM1A, NM4, NM5 and NM6. A correction of +3 dB(A) was applied to the free field measurements.

b. Façade measurements were made at the monitoring station NM3A.

c. Parameters such as frequency weighting, time weighting and measurement time were set.

d. Prior to and after each noise measurement, the meter was calibrated using the acoustic calibrator. If the difference in the calibration level before and after measurement was more than 1 dB(A), the measurement would be considered invalid and repeat of noise measurement would be required after re-calibration or repair of the equipment.

e. During the monitoring period, Leq, L10 and L90 were recorded. In addition, site conditions and noise sources were recorded on a record sheet.

f. Noise measurement results were corrected with reference to the baseline monitoring levels.

g. Observations were recorded when high intrusive noise (e.g. dog barking, helicopter noise) was observed during the monitoring.

3.4.2

Maintenance and

Calibration

The maintenance and calibration procedures are summarised below:

a. The microphone head of the sound level meter was cleaned with soft cloth at regular intervals.

b. The meter and calibrator were sent to the supplier or laboratory accredited under Hong Kong Laboratory Accreditation Scheme (HOKLAS) to check and calibrate at yearly intervals.

Calibration certificates of the sound level meters and acoustic calibrators used in the noise monitoring are provided in Appendix B.

3.5

Analysis and Interpretation of Monitoring Results

The construction noise monitoring results are summarized in Table 3.4 and the detailed monitoring data are provided in Appendix D.

Table 3.4: Summary of Construction Noise Monitoring Results

|

Monitoring Station |

Noise Level Range, dB(A) Leq (30 mins) |

Limit Level, dB(A) Leq (30 mins) |

|

NM1A(i) |

71- 73 |

75 |

|

NM3A |

61- 63 |

75 |

|

NM4(i) |

60- 66 |

70(ii) |

|

NM5(i) |

53- 59 |

75 |

|

NM6(i) |

66- 74 |

75 |

Note: (i) +3 dB(A) Façade correction included;

(ii) Reduced to 65 dB(A) during school examination periods.

As the construction activities were small in scale during the reporting period and far away from the monitoring stations, major sources of noise dominating the monitoring stations observed during the construction noise impact monitoring were aircraft noise at NM3A and NM5, aircraft noise and helicopter noise at NM6, road traffic noise at NM1A and school activities at NM4 in this reporting month.

No exceedance of the Action/ Limit Level was recorded at all monitoring stations in the reporting period.

4.1

Monitoring Requirements

In accordance with the Updated EM&A Manual, the waste generated from construction activities was audited once per week to determine if wastes are being managed in accordance with the Waste Management Plan (WMP) prepared for the Project, contract-specific WMP, and any statutory and contractual requirements. All aspects of waste management including waste generation, storage, transportation and disposal were assessed during the audits. The Action and Limit levels of the construction waste are provided in Table 4.1.

Table 4.1: Action and Limit Levels for Construction Waste

|

Monitoring Stations |

Action Level |

Limit Level |

|

Construction Area |

When one valid documented complaint is Received |

Non-compliance of the WMP, contract-specific WMPs, any statutory and contractual requirements |

4.2

Waste Management Status

Weekly monitoring of the Project construction works was carried out by the ET on 4, 11, 18 and 25 May 2016 to check and monitor the implementation of proper waste management practices during the construction phase.

For Contract P560(R) Aviation Fuel Pipeline Diversion Works, recommendations were provided during monitoring including the provision of drip tray for equipment to avoid oil leakage and provision of spill kit on sites on 25 May 2016. The contractor had followed up with implementation of mitigation measures.

The P560(R) Contractor was advised to properly maintain a recording system, maximize the reuse of C&D materials and properly maintain site tidiness.

Based on the updated information, about 46m3 and 5m3 excavated materials were produced from the HDD launching site in April and May 2016 respectively. The generated excavated materials were temporarily stored at storage and stockpiling area at Chun Ming Road adjacent to Tradeport Logistic Centre on the airport island. The excavated material will be reused in the Project.

In addition, 1.12 tonnes of general refuse were disposed of to the West New Territories (WENT) Landfill in May 2016. No Construction and Demolition (C&D) material was disposed off-site during the reporting month. No exceedances of the Action and Limit Levels were recorded in the reporting period.

5.1

Weekly Environmental Site Inspection

Weekly site inspection of the construction works was carried out by the ET on 4, 11, 18 and 25 May 2016 to monitor the implementation of proper environmental pollution control and mitigation measures for the Project. Site inspections were also conducted independently by the Project’s Independent Environmental Checker (IEC) on 11 and 25 May 2016. Observations have been recorded in the site inspection checklists and passed to the Contractor together with the appropriate recommended mitigation measures where necessary.

The key observations from site inspection and associated recommendations were related to the improvement of efficiency and capacity of wastewater treatment facilities, provision of drip tray for equipment and provision of spill kit on sites. Dust suppression measures including provision of wheel washing facilities, watering of unpaved site area, covering of excavated materials and establishment of site hoarding have been implemented. Improvement of capacity of wastewater treatment facility at the stockpiling site was in-progress to provide better management of site runoff.

A summary of implementation status of the environmental mitigation measures for the construction phase of the Project during the reporting period is provided in Appendix A.

5.2

Audit of Route

Diversion and Speed Control of the SkyPier High Speed

Ferries

The Marine Travel Routes and Management Plan for High Speed Ferries of SkyPier (the SkyPier Plan) has been submitted to the Advisory Council on the Environment (ACE) for comment and subsequently submitted to and approved by EPD in November 2015 under EP Condition 2.10. The approved SkyPier Plan is available on the dedicated website of the Project. In the SkyPier Plan, AAHK committed to implementing the mitigation measure of requiring high speed ferries (HSFs) of SkyPier travelling between HKIA and Zhuhai / Macau to start diverting the route with an associated speed control across an area (i.e. Speed Control Zone (SCZ)) with high Chinese White Dolphin (CWD) abundance. The route diversion and speed restriction at the SCZ have been implemented since 28 December 2015.

Key audit findings for the SkyPier HSFs travelling to/from Zhuhai and Macau against the requirements of the SkyPier Plan during the reporting period are summarized in Table 5.1. The daily movements of all SkyPier HSFs in May 2016 were within the maximum daily cap number. Status of compliance with annual daily average of 99 movements will be further reviewed in the annual EM&A Report.

In total, 837 ferry movements between HKIA SkyPier and Zhuhai / Macau were recorded in May 2016 and the data are presented in Appendix G. The time spent for the SkyPier HSFs travelled through the SCZ in May were presented in Figure 5-1. It will take 9.6 minutes to travel through the SCZ when the SkyPier HSFs adopt the maximum allowed speed of 15-knot within the SCZ. Figure 5-1 shows that all the SkyPier HSFs spent more than 9.6 minutes to travel through the SCZ and the SkyPier HSFs had travelled through the SCZ with prevailing speeds ranging from 7.8 to 14.7 knots.

Figure 5‑1 Duration of the SkyPier HSFs travelled through the SCZ for May 2016

One ferry movement was not strictly following the diverted route as recorded on 16 May 2016. Notice was sent to the ferry operators and the investigation results revealed that they were related to safety / emergency situations presented as follows:

¡ Case on 16 May 2016: HSF captain reported that he had to give way to other vessels for safety reason and was not able to enter the SCZ through the gate access points. Then the HSF returned to the normal route following the SkyPier Plan.

Two HSF movements with no transmission of AIS data received on 30 May 2016 were reported. After investigation, it was found that missing of AIS data for the concerned ferry was due to error of the AIS system. Follow up action will be undertaken with the concerned Ferry Operator.

Two skipper workshops were held on 25 and 26 May 2016 as refresher trainings to ferry captains about the requirements of the SkyPier Plan.

Table 5.1: Summary of Key Audit Findings against the SkyPier Plan

|

Requirements in the SkyPier Plan |

1 May to 31 May 2016 |

|

Total number of ferry movements recorded and audited |

837 (2 HSF movements without AIS data) |

|

Use diverted route and enter / leave SCZ through Gate Access Points |

1 deviations (related to safety/emergency) |

|

Speed control in speed control zone |

All HSFs were within 15 knots (7.8 to 14.7 knots), which complied with the SkyPier Plan. The time used by HSF to travel through SCZ is presented in Figure 5-1. |

|

Daily Cap (including all SkyPier HSFs)

|

88 to 95 daily movements (within maximum daily cap - 125 daily movements) |

5.3

Status of

Submissions under Environmental Permits

The current status of submissions under the EP up to the reporting period is presented in Table 5.2.

Table 5.2: Status of Submissions under Environmental Permit

|

EP Condition |

Submission |

Status |

|

2.1 |

Complaint Management Plan |

Accepted / approved by EPD

|

|

2.4 |

Management Organizations |

|

|

2.5 |

Construction Works Schedule and Location Plans |

|

|

2.7 |

Marine Park Proposal |

|

|

2.8 |

Marine Ecology Conservation Plan |

|

|

2.9 |

Marine Travel Routes and Management Plan for Construction and Associated Vessels |

|

|

2.10 |

Marine Travel Routes and Management Plan for High Speed Ferries of SkyPier |

|

|

2.11 |

Marine Mammal Watching Plan |

Submitted to EPD |

|

2.12 |

Coral Translocation Plan |

|

|

2.13 |

Fisheries Management Plan |

Accepted / approved by EPD |

|

2.14 |

Egretry Survey Plan |

|

|

2.15 |

Silt Curtain Deployment Plan |

Submitted to EPD |

|

2.17 |

Detailed Plan on Deep Cement Mixing |

|

|

2.16 |

Spill Response Plan |

Accepted / approved by EPD |

|

2.19 |

Waste Management Plan |

|

|

3.1 |

Updated EM&A Manual |

|

|

3.4 |

Baseline Monitoring Report |

5.4

Compliance with

Other Statutory Environmental Requirements

During the reporting period, environmental related licenses and permits required for the construction activities were checked. No non-compliance with environmental statutory requirements was recorded. The environmental licenses and permits which are valid in the reporting month are presented in Appendix E.

5.5

Analysis and

Interpretation of Complaints, Notification of Summons and Status of

Prosecutions

5.5.1

Complaints

During the reporting period, no construction activities related complaints were received.

5.5.2

Notifications of

Summons or Status of Prosecution

During the reporting period, neither notifications of summons nor prosecution were received.

5.5.3

Cumulative

Statistics

Cumulative statistics on complaints, notifications of summons and status of prosecutions are summarized in Appendix F.

6.1

Construction Programme for the Coming Reporting Period

Major site activities anticipated in the next reporting period for the Project are expected to be associated with the implementation of the P560(R) Contract and these will include:

¡ HDD casing pipe installation; and

¡ Stockpiling of excavated materials from HDD operation.

No construction works will be carried out on Sheung Sha Chau Island during the ardeids’ breeding season between April and July in accordance with the Updated EM&A Manual.

6.2

Key Environmental Issues for the Coming Reporting Period

The key environmental issues for the Project in the coming reporting period are expected to be associated with the construction activities of the P560(R) Contract and these include:

¡ Generation of dust from construction works;

¡ Noise impact from operating equipment and machinery on-site;

¡ Generation of site surface runoffs and wastewater from activities on-site;

¡ Management of stockpiles;

¡ Sorting, recycling, storage and disposal of general refuse and construction waste; and

¡ Management of chemicals and avoidance of oil spillage on-site.

6.3

Monitoring

Schedule for the Coming Reporting Period

A tentative schedule of the planned environmental monitoring work in the next reporting period is provided in Appendix C.

6.4

Other EIA / EM&A Issues

6.4.1

On-going and Fore-coming

Baseline Monitoring

Baseline monitoring of CWD by vessel surveys, land-based theodolite tracking and passive acoustic monitoring (PAM) are ongoing. The baseline monitoring results will be presented in a separate Baseline Monitoring Report for the marine works.

Baseline water quality monitoring had been completed in May 2016. The baseline monitoring results will be presented in a separate Baseline Monitoring Report for the marine works.

The key construction activities of the Project carried out in the reporting month were related to the Contract P560 Aviation Fuel Pipeline Diversion Works which involved installation of HDD casing and antenna farm structural protection works. Dust suppression measures including wheeling washing, watering and covering of excavated materials and establishment of site hoarding have been implemented.

Construction dust, noise and waste monitoring were carried out in the reporting period. No breach of the Action or Limit Levels in relation to the air quality, construction noise and waste monitoring were recorded in the reporting month. All site observations made by the ET were recorded in the site inspection checklists and passed to the Contractor together with the recommended follow-up actions.

On the implementation of the SkyPier Plan, the daily movements of all SkyPier HSFs in May 2016 were within the maximum daily cap number. A total of 837 HSF movements under SkyPier Plan were recorded. All HSFs had travelled through the SCZ with prevailing speed under 15 knots (7.8 to 14.7 knots) in compliance with the SkyPier Plan. There was one case of not fully following the diverted route and investigation results revealed that the case was related to safety/emergency situations. In summary, the ET and IEC have audited the HSF movements against the SkyPier Plan and conducted follow up investigation or actions accordingly.